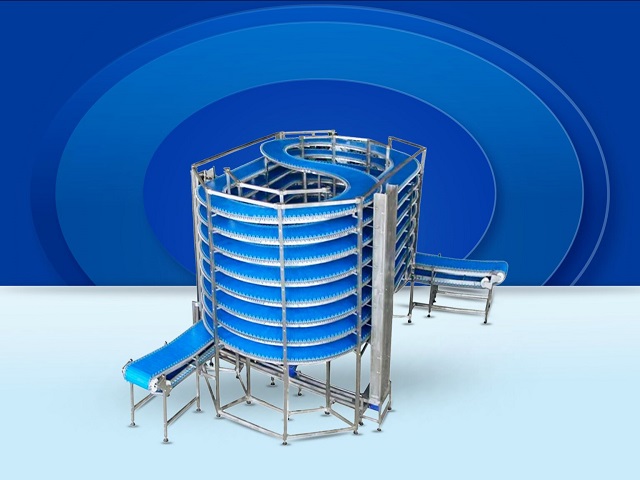

Spiral Conveyor Dryers

Spiral Conveyor Dryers

The Industrial spiral conveyor dryers are tools for continuously drying a range of items. They are frequently utilised in the food processing, pharmaceutical, chemical, and other manufacturing sectors where drying is an essential stage of the manufacturing process. A spiral conveyor dryer’s primary function is to eliminate moisture or solvents from items, bringing their moisture content to a desired level.

Efficiency and Performance

Safety Features

Durability and Build Quality

Customization and Versatility

Compliance and Certifications

Environmental Considerations

- Microwave Heating Dryer

- Radio Frequency Heating Dryer

- Conventional Heating Dryer

- Infrared Dryers

- Hot Air Dryer

- Pneumatic/ Flash Dryer

- Spray Dryer

- Drum Dryers

- Box Dryers

- Heat Pump Dryers

- Imperial and Band Dryer

- Coal/Briquette Dryer

- Tunnel Dryers

- Contact Drying- Steam Cylinders/Cans

- Fluidised Bed Dryers

- Rotary Dryers

- Tower Dryers

- Tray Dryers

- Fish Dryer

- Spiral Conveyor Dryers

- Microwave Spices Dryer

- Food Dryers/Food Dehydrator

- Freeze Dryers

- Coir Pith Dryers

- Conveyorised Organic Waste Dryers

- Screw Dryer

- Rotary Dryer

- Fluidised Bed Dryers

- Spray Dryers

- Sludge Dryers

- Agitated Thin Film Dryers

- Rotary Tube Bundle Dryers

- Biomass Dryer

- Manure Organic Fertilizer Dryer

- Cocopeat Coir Dryer Machine

- Coal Dryer Machine System

- Carbonization Machine

The Kerone Engineering Solutions Ltd. Spiral Conveyors System is built on cutting-edge technology and provides a wealth of features and advantages. In addition to being faster and more dependable than any lift or lift, spiral conveyors from KERONE use less floor space than conventional conveyors. The innovative slat-type belts, which have rolling friction but no sliding motions or wear-strips, are at the core of our design.

Over the course of our more than 48 years in business, Kerone has assisted numerous industries with the planning, production, and installation of different kinds of specialised industrial spiral drying solutions. In the automated production process, Kerone Spiral Dryers are very helpful and can be utilised to transport a variety of solid items or solid-liquid combinations, from loose materials and produced goods to completed, packaged products.

The Industrial spiral conveyor dryers are tools for continuously drying a range of items. They are frequently utilised in the food processing, pharmaceutical, chemical, and other manufacturing sectors where drying is an essential stage of the manufacturing process. A spiral conveyor dryer’s primary function is to eliminate moisture or solvents from items, bringing their moisture content to a desired level.

The spiral conveyor automates production procedures, boosts profitability, and frees up production space. Among food producers, these conveyor systems are already well-liked. The industrial spiral conveyor system that is given is used to carry goods from floor to floor as well as in other specialised orientations, including from top to bottom and from bottom to top.

The productivity of a spiral application can be greatly increased by using a spiral conveyor dryer. Low price, good effectiveness. To increase efficiency, reduce expenses, and remove the production line’s bottleneck. Its capabilities include the ability to manage various support processes, such as stirring, mixing, heating, and cooling operations during conveying; it is also ideal for managing the transportation requirements of granular materials, such as mineral powder, cement powder, fly ash, sand, coal, and others.

- Highly flexible Design and Technology.

- Easy Maintenance

- Low cost of operation

- Controlled Pollution Level

- Energy saving

- Easy Operating

- Fast, easy installation

- Food processing

- Agriculture

- Chemical

- Pharmaceutical

- Foundry

We at Kerone Engineering are pleased to be your first choice for all engineering solution needs. With great pleasure, we announce that we can now provide our excellent complete engineering solutions not just state-wide but now throughout India.

We expand to ensure that our innovative and dependable heating, cooling and drying products are available to various industries across the globe because of our dedication to quality and client satisfaction. Kerone Engineering is prepared to assist you, no matter where you are in India and overseas.

We Supply and Export in Listed City & States.

Raipur | Bilaspur | Panaji | Vasco da Gama | Gandhinagar | Ahmedabad | Surat | Chandigarh | Faridabad | Gurgaon | Shimla | Manali | Ranchi | Jamshedpur | Bengaluru | Mysore | Thiruvananthapuram | Kochi | Bhopal | Indore | Gwalior | Jabalpur | Mumbai | Thane | Navi Mumbai | Pune | Palghar | Imphal | Shillong | Aizawl | Kohima | Bhubaneswar | Cuttack | Chandigarh | Amritsar | Jaipur | Udaipur | Pali | Jodhpur | Ajmer | Bikaner | Kota | Gangtok | Chennai | Coimbatore | Hyderabad | Warangal | Agartala | Lucknow | Kanpur | Dehradun | Haridwar | Kolkata | Howrah | Itanagar | Naharlagun Dispur | Guwahati Patna | Gaya

Arunachal Pradesh | Assam | Bihar | Chhattisgarh | Delhi |Goa | Gujarat | Haryana | Himachal Pradesh | Jharkhand | Karnataka | Kerala | Madhya Pradesh | Maharashtra | Meghalaya | Mizoram | Nagaland | Odisha | Manipur | Punjab | Rajasthan | Sikkim | Tamil Nadu | Telangana | Tripura | Uttar Pradesh | Uttarakhand | West Bengal

We Supply and Export in Listed Country.

India | Bhutan | Burma | Qatar | UAE | Israel | Italy | Japan | Kazakhstan | Kuwait | Latin America | Nepal | Nigeria | Oman | Philippines | Russia | Sri lanka | Singapore | Sudan | Uganda | US | UK | Europe | Madagascar | Venezuela | Yemen | Ghana | Angola | Malaysia | Peru | Uzbekistan | Saudi Arabia | Morocco | Poland | Canada | Ukraine | Algeria | Argentina | Spain | Colombia | Kenya | Myanmar | South Africa | Tanzania | France | Australia | Thailand | Germany | Turkey | Vietnam | Egypt | Ethiopia | Bangladesh | Brazil | Indonesia | China |