Imperial and Band Dryer

Imperial and Band Dryer

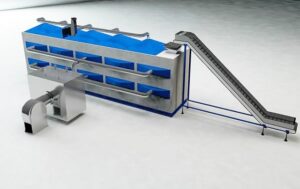

At Kerone, we manufacture premium band dryers that are a part of the continuous conventional heat transfer dryer family. Conveyor belts are stacked one on top of the other to create Imperial and Band dryers. Long residence times and several passes are made possible on constrained floor space by multilayer. Band dryers are built using a number of modular components, each with its own heating and air circulation system. The often used continuous band drier consists of a single pass conveyor that circulates air.

Efficiency and Performance

Safety Features

Durability and Build Quality

Customization and Versatility

Compliance and Certifications

Environmental Considerations

- Microwave Heating Dryer

- Radio Frequency Heating Dryer

- Conventional Heating Dryer

- Infrared Dryers

- Hot Air Dryer

- Pneumatic/ Flash Dryer

- Spray Dryer

- Drum Dryers

- Box Dryers

- Heat Pump Dryers

- Imperial and Band Dryer

- Coal/Briquette Dryer

- Tunnel Dryers

- Contact Drying- Steam Cylinders/Cans

- Fluidised Bed Dryers

- Rotary Dryers

- Tower Dryers

- Tray Dryers

- Fish Dryer

- Spiral Conveyor Dryers

- Microwave Spices Dryer

- Food Dryers/Food Dehydrator

- Freeze Dryers

- Coir Pith Dryers

- Conveyorised Organic Waste Dryers

- Screw Dryer

- Rotary Dryer

- Fluidised Bed Dryers

- Spray Dryers

- Sludge Dryers

- Agitated Thin Film Dryers

- Rotary Tube Bundle Dryers

- Biomass Dryer

- Manure Organic Fertilizer Dryer

- Cocopeat Coir Dryer Machine

- Coal Dryer Machine System

- Carbonization Machine

At Kerone, we manufacture premium band dryers that are a part of the continuous conventional heat transfer dryer family. Conveyor belts are stacked one on top of the other to create Imperial and Band dryers. Long residence times and several passes are made possible on constrained floor space by multilayer. Band dryers are built using a number of modular components, each with its own heating and air circulation system. The often used continuous band drier consists of a single pass conveyor that circulates air.

The Industrial drying machine in the food processing sector is the Imperial Dryer. It is intended to dry out food products, preserving their quality and lengthening their shelf life. Through the product, warm air or gas is circulated by the dryer, assisting in the evaporation of moisture. The product is moved through the drying chamber of the Imperial Dryer, where it is exposed to the drying medium, using a conveyor belt or tray system. To get the product’s desired moisture content, drying parameters including temperature, airflow, and residence time can be changed.

A continuous drying device used in a variety of sectors, including textiles, chemicals, and pharmaceuticals is referred to as a band dryer, also known as a belt dryer. For drying bulk materials, powders, granules, or other solid forms, it is especially effective. The product is moved through various heating zones by a number of perforated belts or bands that make up the dryer. The moving bands are exposed to hot air or gas, which speeds up the evaporation of moisture from the substance. To guarantee effective and consistent drying, the drying process is normally managed by regulating the temperature, airflow, and belt speed.

Type of conveyor supported

- Continuous perforated belt

- Hinged perforated plates

- Wire mesh

- Wire and struts belt

Industry Applications

- Energy saving due to gas recycling

- Highly homogeneous treatment

- Adjustment of temperature, gas velocity and direction in each section

- Multiple processing in one single equipment

- Versatility of processes and applications

- Accurate adjustment of residence time

- Possibility to add accessories for mechanical action on product

Features

- Easy zoning: The temperature, humidity and airflow speed can be easily set and controlled for each zone

- Uniform Drying: The drying time can be easily attuned to achieve consistent heat progress, results in evenness of drying across product.

- Clean Drying: Materials are dried with in the band dryer’s chamber with uniform moving speed this results in minimum damage and dust sprinkle.

- Product suitability: Band dryer allows grinding and shaping of sludge or irregularly shaped materials.

- Multi Staging: Band dryers can be made with single stage or multi stage with capability to handle both high volume and low volume.

- Customizable: Imperial and band dryers can be made with different configurations such as heat source (Hot Air, Oil, electric etc.), humidity (humidifier, dehumidifier etc.) and air circulation (from top, down, vertical, horizontal etc.)

We at Kerone Engineering are pleased to be your first choice for all engineering solution needs. With great pleasure, we announce that we can now provide our excellent complete engineering solutions not just state-wide but now throughout India.

We expand to ensure that our innovative and dependable heating, cooling and drying products are available to various industries across the globe because of our dedication to quality and client satisfaction. Kerone Engineering is prepared to assist you, no matter where you are in India and overseas.

We Supply and Export in Listed City & States.

Raipur | Bilaspur | Panaji | Vasco da Gama | Gandhinagar | Ahmedabad | Surat | Chandigarh | Faridabad | Gurgaon | Shimla | Manali | Ranchi | Jamshedpur | Bengaluru | Mysore | Thiruvananthapuram | Kochi | Bhopal | Indore | Gwalior | Jabalpur | Mumbai | Thane | Navi Mumbai | Pune | Palghar | Imphal | Shillong | Aizawl | Kohima | Bhubaneswar | Cuttack | Chandigarh | Amritsar | Jaipur | Udaipur | Pali | Jodhpur | Ajmer | Bikaner | Kota | Gangtok | Chennai | Coimbatore | Hyderabad | Warangal | Agartala | Lucknow | Kanpur | Dehradun | Haridwar | Kolkata | Howrah | Itanagar | Naharlagun Dispur | Guwahati Patna | Gaya

Arunachal Pradesh | Assam | Bihar | Chhattisgarh | Delhi |Goa | Gujarat | Haryana | Himachal Pradesh | Jharkhand | Karnataka | Kerala | Madhya Pradesh | Maharashtra | Meghalaya | Mizoram | Nagaland | Odisha | Manipur | Punjab | Rajasthan | Sikkim | Tamil Nadu | Telangana | Tripura | Uttar Pradesh | Uttarakhand | West Bengal

We Supply and Export in Listed Country.

India | Bhutan | Burma | Qatar | UAE | Israel | Italy | Japan | Kazakhstan | Kuwait | Latin America | Nepal | Nigeria | Oman | Philippines | Russia | Sri lanka | Singapore | Sudan | Uganda | US | UK | Europe | Madagascar | Venezuela | Yemen | Ghana | Angola | Malaysia | Peru | Uzbekistan | Saudi Arabia | Morocco | Poland | Canada | Ukraine | Algeria | Argentina | Spain | Colombia | Kenya | Myanmar | South Africa | Tanzania | France | Australia | Thailand | Germany | Turkey | Vietnam | Egypt | Ethiopia | Bangladesh | Brazil | Indonesia | China |