Fly ash drying system plays a crucial role in the processing of industrial waste by efficiently removing moisture from fly ash, a fine powder residue generated from coal combustion in thermal power plants.

Coal is among the most critical sources of energy generation in the world since the global electricity generated from it is extremely high. However, coal combustion produces some waste materials that are not desirable, the most well-known of which is fly ash. Fly ash has environmental and handling disadvantages, thus the need for proper methods to be adopted. One of the solutions that might help is the fly ash/coal dryer system, a complex technology which deals with handling, processing, and elimination of problematic aspects of fly ash.

What is Fly Ash/Coal Ash?

Fly ash drying is generally termed as coal ash and is in the form of a fine, powdery substance resulting from the combustion of coal plants or thermals. Again, it mainly contains oxides of inorganic materials like silica, alumina and calcium, and minor percentages of heavy metals like arsenic, lead and mercury. This byproduct results from the accumulation of coal’s mineral impurities when the burning process occurs. It is carried by the flue gases and collected through various emission control technologies such as electrostatic precipitators and baghouses. This property makes it used as a supplementary cementitious material in cement and concrete, enhancing its strength and durability while at the same time being environmental friendly. Yet, its misuse poses serious environmental and health risks, especially to the quality of the air as well as the water.

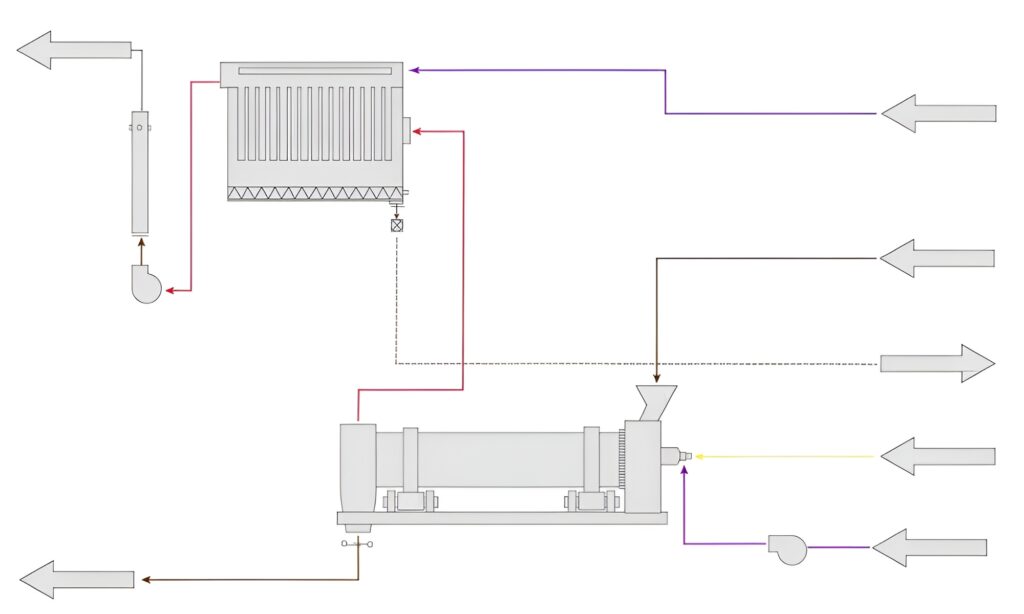

The Process of Fly Ash Drying System

Fly ash is a byproduct obtained from the combustion of coal in power plants and drying is one of the methods of fly ash processing in order to achieve different qualities for multiple uses. First, wet non sintered or raw fly ash is derived from the electrostatic precipitators or baghouses. It is then taken to the drying plant so that it undergoes a pre-drying process that seek to eliminate the moisture content on the fly ash. The first stage of the process is relatively simple and involves the use of rotary dryers or fluidized bed dryers to evaporate any of the moisture that might still be present. In this phase, the fly ash is also stirred continuously to allow regular flow pattern for proper drying as well as to avoid any accumulation.

The temperature, flow rate of air and the residence time specific to each dryer is adjusted to reduce the moisture in the mixture to the correct percentage but not to harm the formed ash particles. Upon drying, the fly ash is cooled and what is commonly done is to screen the fly ash or mill it to ensure that the fly ash drying particles are of the right size. The fly ash is then further dried and if required can be stocked in silos or can be directly utilized in the making of concrete and roads or as filler materials for other processes. This drying process does not only increase the possibility of its useful application but also reduces waste material output contributing to the good of the environment.

Uses of Fly Ash / Coal Ash

Fly ash is the fine microscopic particles of coal which are produced during combustion of coal in thermal power plants and possesses multiple uses. One of the broad uses of silica sand is in the construction industry where it widely used as an essential ingredient in concrete and cement preparation. Some of the benefits of fly ash when included in concrete include improvements in workability and strength, reduction in permeability, and enhanced strength and durability over the long term.

Also, it aids in the production of high strength concrete, which had better resistance to chemical aggression and less heat of hydration. Fly ash drying is also incorporated in production of bricks, blocks and tiles where they can be used instead of clay products which are motioned here. In environmental management, fly ash is widely used in environmental, civil engineering, and soil subdivisions as well as in management of contaminated land and hazardous wastes.

Its applications in the manufacturing of lightweight aggregates; construction of roads; utilization in the production of specific kinds of synthetic gypsum also demonstrate that. Also, apprehensively, fly ash could reduce greenhouse gas emissions to some extent for every percentage of cement replaced by fly ash in concrete construction projects. The use of Fly Ash Drying serves to both minimize the effects of environmental issues associated with its disposal as well as actively contributing to the advancement of sustainable constructional technologies by providing an effective and sustainable solution to the enhancement of the performance and durability of many constructional products.

Advantages of Fly Ash / Coal Ash Dryers

The various advantages of fly ash drying or coal ash dryers are as follows when it comes to handling and processing the two industrial associates. They mostly cause a considerable decrease in variability of the moisture content of fly ash enhancing its handling and transportability. This drying is necessary to minimize the tendency of the ash to cluster and turn into a paste-like substance which would affects its flow ability, making its disposal easier and faster. Also, there are benefits of fly ash drying since it enables the product to be used in numerous processes like making of concrete where the material will have boost up strength and stability. It also helps to avoid such dangerous factors for the environment as leachate and groundwater contamination as well as to decrease the total amount of moisture content. In addition, the dried ash can be Utilized much more efficiently in manufacturing, which in-turn leads to the conservation of raw materials. In conclusion, fly ash drying increase the effectiveness of the operation, protect the environment, and create higher market utility of fly ash.

Kerone have been able to specialize and provide innovative drying solutions for the coal power plant and similar industries. Using modernity and efficiency, Kerone achieves the main goal of fly ash drying in the shortest time and with minimal moisture content, thereby improving the quality of material and adhering to environmental objectives. With the increased pressure to embrace green solutions, ensures that the efforts made by companies such as Kerone in developing the fly ash drying technology go a long way in supporting environmentally sustainable power production and management of wastes in different parts of the world.