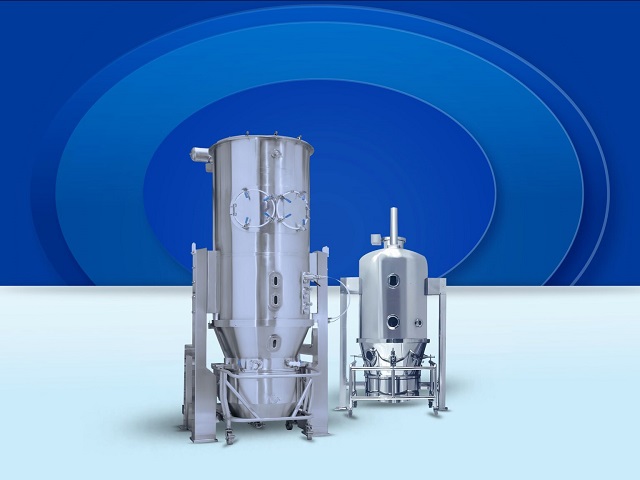

Fluidized Bed Dryer

Fluidized Bed Dryer

Fluidized bed dryers from Kerone Engineering Solutions Ltd. are useful for drying molten materials, pastes, solutions, suspensions, and granular materials in batch and continuous models. Kerone offers a full range of services, including design, production, erection, commissioning, and post-installation support. We have more than 48 years of expertise offering high-quality goods and services in the drying and heating sector

Efficiency and Performance

Safety Features

Durability and Build Quality

Customization and Versatility

Compliance and Certifications

Environmental Considerations

- Microwave Heating Dryer

- Radio Frequency Heating Dryer

- Conventional Heating Dryer

- Infrared Dryers

- Hot Air Dryer

- Pneumatic/ Flash Dryer

- Spray Dryer

- Drum Dryers

- Box Dryers

- Heat Pump Dryers

- Imperial and Band Dryer

- Coal/Briquette Dryer

- Tunnel Dryers

- Contact Drying- Steam Cylinders/Cans

- Fluidised Bed Dryers

- Rotary Dryers

- Tower Dryers

- Tray Dryers

- Fish Dryer

- Spiral Conveyor Dryers

- Microwave Spices Dryer

- Food Dryers/Food Dehydrator

- Freeze Dryers

- Coir Pith Dryers

- Conveyorised Organic Waste Dryers

- Screw Dryer

- Rotary Dryer

- Fluidized Bed Dryer

- Spray Dryers

- Sludge Dryers

- Agitated Thin Film Dryers

- Rotary Tube Bundle Dryers

- Biomass Dryer

- Manure Organic Fertilizer Dryer

- Cocopeat Coir Dryer Machine

- Coal Dryer Machine System

- Carbonization Machine

Fluidized bed dryers from Kerone Engineering Solutions Ltd. are useful for drying molten materials, pastes, solutions, suspensions, and granular materials in batch and continuous models. Kerone offers a full range of services, including design, production, erection, commissioning, and post-installation support. We have more than 48 years of expertise offering high-quality goods and services in the drying and heating sector

A gas stream is passed through a bed of particle solids to create a fluidized bed. The bed remains static and the particles are spread out on a gas distribution plate when the gas velocity is low. The distributor distributes the fluidizing gas evenly across the bed as it passes through. The lowest fluidization velocity is the gas velocity at which the bed achieves fluidization. Gas velocity is increased in this manner to accomplish fluidization of bed. A fluidized bed dryer runs at a gas velocity greater than the material being processed’s minimum fluidization velocity. This increase in gas velocity causes particles processed in air to be suspended, which manifests as the boiling of solid particles of material beneath

The fluidized bed dryer offered efficient solid mixing, rapid heat and mass transfer, and material transportation. In comparison to other traditional drying techniques, fluidized bed dryers are more suited for drying fine powder particles with sizes between 10 and 2000 mm.

A popular form of industrial drying apparatus for effectively drying solid materials is the fluidized bed dryer. They work on the idea of fluidization, suspending and moving the material in a high-velocity stream of hot air or gas to create a fluid-like state inside the drying chamber. This fluidized state enables efficient heat transfer and even drying across the whole surface of the material.

The wet or moist material into the drying chamber is a typical step in the fluidized bed drying process. The substance is then made to become suspended and behave like a fluid when a controlled stream of hot air or gas is then injected from the chamber’s bottom through a distributor. Heat is transferred and moisture evaporation occurs as the hot gas travels through the fluidized bed in direct contact with the wet material. The material is ejected from the dryer with the moisture that has evaporated having been removed by the gas stream.

Features

- Materials dried in a constant-rate drying

- Drying of material with low moisture content, under a relatively low temperature.

- Suitable for granules or crystallized materials as there is no damage to particles.

- High drying efficiency

- Modular Design

- Uniform Drying with reducing Drying time

- Provides extended residence times

- Fireproof Construction

- Easy to remove/change heat exchanger

- Flexibility of residence time and temperatures

Application

- Chemicals

- Carbohydrates

- Foodstuff

- Biomaterials

- Beverage Products

- Ceramics

- Pharmaceuticals in Powder or Agglomerated Form

- Health- Care Products

- Pesticides and Agrochemicals

- Dyestuffs and Pigments

- Detergents and Surface-Active Agents

- Fertilizers

- Polymer and Resins

- Tannins

- Products for Calcination

- Combustion

- Incineration

- Waste Management Processes

- Environmental Protection Pro- Cesses

We at Kerone Engineering are pleased to be your first choice for all engineering solution needs. With great pleasure, we announce that we can now provide our excellent complete engineering solutions not just state-wide but now throughout India.

We expand to ensure that our innovative and dependable heating, cooling and drying products are available to various industries across the globe because of our dedication to quality and client satisfaction. Kerone Engineering is prepared to assist you, no matter where you are in India and overseas.

We Supply and Export in Listed City & States.

Raipur | Bilaspur | Panaji | Vasco da Gama | Gandhinagar | Ahmedabad | Surat | Chandigarh | Faridabad | Gurgaon | Shimla | Manali | Ranchi | Jamshedpur | Bengaluru | Mysore | Thiruvananthapuram | Kochi | Bhopal | Indore | Gwalior | Jabalpur | Mumbai | Thane | Navi Mumbai | Pune | Palghar | Imphal | Shillong | Aizawl | Kohima | Bhubaneswar | Cuttack | Chandigarh | Amritsar | Jaipur | Udaipur | Pali | Jodhpur | Ajmer | Bikaner | Kota | Gangtok | Chennai | Coimbatore | Hyderabad | Warangal | Agartala | Lucknow | Kanpur | Dehradun | Haridwar | Kolkata | Howrah | Itanagar | Naharlagun Dispur | Guwahati Patna | Gaya

Arunachal Pradesh | Assam | Bihar | Chhattisgarh | Delhi |Goa | Gujarat | Haryana | Himachal Pradesh | Jharkhand | Karnataka | Kerala | Madhya Pradesh | Maharashtra | Meghalaya | Mizoram | Nagaland | Odisha | Manipur | Punjab | Rajasthan | Sikkim | Tamil Nadu | Telangana | Tripura | Uttar Pradesh | Uttarakhand | West Bengal

We Supply and Export in Listed Country.

India | Bhutan | Burma | Qatar | UAE | Israel | Italy | Japan | Kazakhstan | Kuwait | Latin America | Nepal | Nigeria | Oman | Philippines | Russia | Sri lanka | Singapore | Sudan | Uganda | US | UK | Europe | Madagascar | Venezuela | Yemen | Ghana | Angola | Malaysia | Peru | Uzbekistan | Saudi Arabia | Morocco | Poland | Canada | Ukraine | Algeria | Argentina | Spain | Colombia | Kenya | Myanmar | South Africa | Tanzania | France | Australia | Thailand | Germany | Turkey | Vietnam | Egypt | Ethiopia | Bangladesh | Brazil | Indonesia | China |