Conveyorised Organic Waste Dryers

Conveyorised Organic Waste Dryers

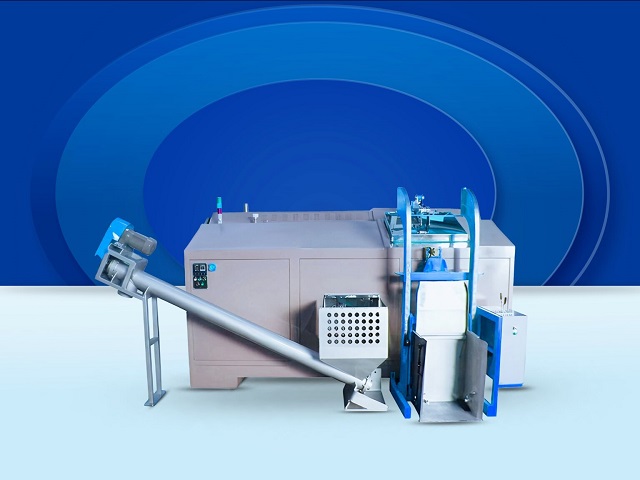

Conveyorised organic waste dryers are specialised drying apparatuses used to process and significantly reduce the moisture content of organic waste materials on a big scale. These dryers use a conveyor belt system to carry the trash constantly through the drying process, guaranteeing effective and consistent drying.

Efficiency and Performance

Safety Features

Durability and Build Quality

Customization and Versatility

Compliance and Certifications

Environmental Considerations

Microwave Heating Dryer

Radio Frequency Heating Dryer

Conventional Heating Dryer

Infrared Dryers

Hot Air Dryer

Pneumatic/ Flash Dryer

Spray Dryer

Drum Dryers

Box Dryers

Heat Pump Dryers

Imperial and Band Dryer

Coal/Briquette Dryer

Tunnel Dryers

Contact Drying- Steam Cylinders/Cans

Fluidised Bed Dryers

Rotary Dryers

Tower Dryers

Tray Dryers

Fish Dryer

Spiral Conveyor Dryers

Microwave Spices Dryer

Food Dryers/Food Dehydrator

Freeze Dryers

Coir Pith Dryers

Conveyorised Organic Waste Dryers

Screw Dryer

Rotary Dryer

Fluidised Bed Dryers

Spray Dryers

Sludge Dryers

Agitated Thin Film Dryers

Rotary Tube Bundle Dryers

Biomass Dryer

Manure Organic Fertilizer Dryer

Cocopeat Coir Dryer Machine

Coal Dryer Machine System

Carbonization Machine

We at Kerone Engineering Solutions Ltd. have more than 48 years of experience assisting different industries with the development, production, and installation of different types of custom-built industrial drying solutions. Understanding the requirements for quality, size, shape, and moisture content of the final dried product must be taken into consideration, as well as production location, building materials most commonly stainless steel, and energy consumption pattern. This is how we assist the customer in choosing.

The material is put into the sealed mixing chamber of our conveyorised organic waste dryers, where it is heated, stirred, and shred during the operation, becoming a dried granular substance. Typically, processing takes eight hours, and the sole waste product is condensed water, which may be safely drained or collected for irrigation.

The operator is left with a dry, stable, and odourless resource that can be used as a biomass fuel to generate heat and hot water or composted using a Rocket Composter as the moisture evaporates during this dehydration phase.

Conveyorised organic waste dryers are specialised drying apparatuses used to process and significantly reduce the moisture content of organic waste materials on a big scale. These dryers use a conveyor belt system to carry the trash constantly through the drying process, guaranteeing effective and consistent drying.

The advantages of conveyorised organic waste dryers are various. They make it possible to process organic waste on a wide scale, lower the volume and weight of the garbage, and enhance its storage and handling capabilities. The dried organic waste can be used in a number of ways, such as anaerobic digestion, composting, or as a sustainable fuel source for energy production.

The dryers are frequently used in industry including waste management facilities, agriculture, and food processing. Conveyorised organic waste dryers support resource recovery, waste reduction, and environmental sustainability by effectively drying organic waste.

- Continuous Conveyor System

- Advanced Drying Technology

- Energy-Efficient Operation

- Customizable Settings

- User-Friendly Interface

- Durable Construction

- Compliance with Environmental Standards

- Resource Recovery

- Scalability

- Comprehensive Support

- Municipal Waste Treatment Plants

- Agricultural Operations

- Food Processing Industries

- Renewable Energy Production

- Hotels and Restaurants

- Wastewater Treatment Plants

- Landfills and Waste Disposal Sites

- Composting Facilities

- Industrial Manufacturing

We at Kerone Engineering are pleased to be your first choice for all engineering solution needs. With great pleasure, we announce that we can now provide our excellent complete engineering solutions not just state-wide but now throughout India.

We expand to ensure that our innovative and dependable heating, cooling and drying products are available to various industries across the globe because of our dedication to quality and client satisfaction. Kerone Engineering is prepared to assist you, no matter where you are in India and overseas.

We Supply and Export in Listed City & States.

Raipur | Bilaspur | Panaji | Vasco da Gama | Gandhinagar | Ahmedabad | Surat | Chandigarh | Faridabad | Gurgaon | Shimla | Manali | Ranchi | Jamshedpur | Bengaluru | Mysore | Thiruvananthapuram | Kochi | Bhopal | Indore | Gwalior | Jabalpur | Mumbai | Thane | Navi Mumbai | Pune | Palghar | Imphal | Shillong | Aizawl | Kohima | Bhubaneswar | Cuttack | Chandigarh | Amritsar | Jaipur | Udaipur | Pali | Jodhpur | Ajmer | Bikaner | Kota | Gangtok | Chennai | Coimbatore | Hyderabad | Warangal | Agartala | Lucknow | Kanpur | Dehradun | Haridwar | Kolkata | Howrah | Itanagar | Naharlagun Dispur | Guwahati Patna | Gaya

Arunachal Pradesh | Assam | Bihar | Chhattisgarh | Delhi |Goa | Gujarat | Haryana | Himachal Pradesh | Jharkhand | Karnataka | Kerala | Madhya Pradesh | Maharashtra | Meghalaya | Mizoram | Nagaland | Odisha | Manipur | Punjab | Rajasthan | Sikkim | Tamil Nadu | Telangana | Tripura | Uttar Pradesh | Uttarakhand | West Bengal

We Supply and Export in Listed Country.

India | Bhutan | Burma | Qatar | UAE | Israel | Italy | Japan | Kazakhstan | Kuwait | Latin America | Nepal | Nigeria | Oman | Philippines | Russia | Sri lanka | Singapore | Sudan | Uganda | US | UK | Europe | Madagascar | Venezuela | Yemen | Ghana | Angola | Malaysia | Peru | Uzbekistan | Saudi Arabia | Morocco | Poland | Canada | Ukraine | Algeria | Argentina | Spain | Colombia | Kenya | Myanmar | South Africa | Tanzania | France | Australia | Thailand | Germany | Turkey | Vietnam | Egypt | Ethiopia | Bangladesh | Brazil | Indonesia | China |