Coir Pith Dryers

Coir Pith Dryers

Coir pith, also known as coco peat or coconut fibre dust, is dried using a machine called a “coir pith dryer.” A byproduct of the production of coir fibre from coconut husks is coir pith. It has many agricultural uses, including as a growing media in horticulture.

Efficiency and Performance

Safety Features

Durability and Build Quality

Customization and Versatility

Compliance and Certifications

Environmental Considerations

Microwave Heating Dryer

Radio Frequency Heating Dryer

Conventional Heating Dryer

Infrared Dryers

Hot Air Dryer

Pneumatic/ Flash Dryer

Spray Dryer

Drum Dryers

Box Dryers

Heat Pump Dryers

Imperial and Band Dryer

Coal/Briquette Dryer

Tunnel Dryers

Contact Drying- Steam Cylinders/Cans

Fluidised Bed Dryers

Rotary Dryers

Tower Dryers

Tray Dryers

Fish Dryer

Spiral Conveyor Dryers

Microwave Spices Dryer

Food Dryers/Food Dehydrator

Freeze Dryers

Coir Pith Dryers

Conveyorised Organic Waste Dryers

Screw Dryer

Rotary Dryer

Fluidised Bed Dryers

Spray Dryers

Sludge Dryers

Agitated Thin Film Dryers

Rotary Tube Bundle Dryers

Biomass Dryer

Manure Organic Fertilizer Dryer

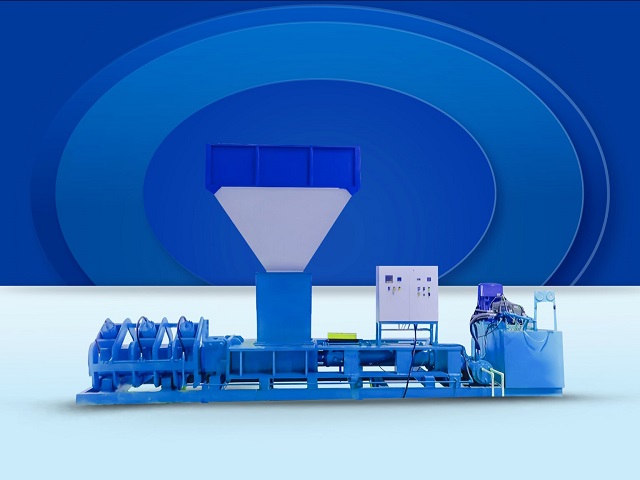

Cocopeat Coir Dryer Machine

Coal Dryer Machine System

Carbonization Machine

We at Kerone Engineering Solution Ltd. have more than 48 years of experience assisting different industries with the development, production, and installation of different types of custom-built industrial drying solutions. Understanding the requirements for quality, size, shape, and moisture content of the final dried product must be taken into consideration, as well as production location, building materials most commonly stainless steel, and energy consumption pattern. This is how we assist the customer in choosing.

Coir pith, also known as coco peat or coconut fibre dust, is dried using a machine called a “coir pith dryer.” A byproduct of the production of coir fibre from coconut husks is coir pith. It has many agricultural uses, including as a growing media in horticulture.

To lower the amount of moisture in coir pith and prepare it for commercial usage, the drying procedure is crucial. The purpose of coir pith dryers is to remove moisture from the material in an efficient and effective manner while maintaining the material’s quality. To accomplish the required drying effect, these dryers frequently use heat and airflow.

The desalination, dehydration, and drying of the coir pith can all be finished in under 40 minutes thanks to a special drying machine that KERONE has created for the production line for drying coir pith. This machine may be connected directly to the machine for opening and sorting coconut shells.

- High Efficiency Heating System

- Controlled Drying Environment

- Uniform Airflow Distribution

- Drying Chamber Design

- Automatic Control Systems

- Energy-Efficient Features

- Safety Features

- Customizable Drying Cycles

- Easy Maintenance and Cleaning

- Dust Collection Systems

Coir pith dryers find extensive application in the coir industry and horticulture sector, playing a crucial role in the processing and utilization of coir pith. Here are the key applications of coir pith dryers:

- Horticulture

- Agriculture

- Animal Bedding

We at Kerone Engineering are pleased to be your first choice for all engineering solution needs. With great pleasure, we announce that we can now provide our excellent complete engineering solutions not just state-wide but now throughout India.

We expand to ensure that our innovative and dependable heating, cooling and drying products are available to various industries across the globe because of our dedication to quality and client satisfaction. Kerone Engineering is prepared to assist you, no matter where you are in India and overseas.

We Supply and Export in Listed City & States.

Raipur | Bilaspur | Panaji | Vasco da Gama | Gandhinagar | Ahmedabad | Surat | Chandigarh | Faridabad | Gurgaon | Shimla | Manali | Ranchi | Jamshedpur | Bengaluru | Mysore | Thiruvananthapuram | Kochi | Bhopal | Indore | Gwalior | Jabalpur | Mumbai | Thane | Navi Mumbai | Pune | Palghar | Imphal | Shillong | Aizawl | Kohima | Bhubaneswar | Cuttack | Chandigarh | Amritsar | Jaipur | Udaipur | Pali | Jodhpur | Ajmer | Bikaner | Kota | Gangtok | Chennai | Coimbatore | Hyderabad | Warangal | Agartala | Lucknow | Kanpur | Dehradun | Haridwar | Kolkata | Howrah | Itanagar | Naharlagun Dispur | Guwahati Patna | Gaya

Arunachal Pradesh | Assam | Bihar | Chhattisgarh | Delhi |Goa | Gujarat | Haryana | Himachal Pradesh | Jharkhand | Karnataka | Kerala | Madhya Pradesh | Maharashtra | Meghalaya | Mizoram | Nagaland | Odisha | Manipur | Punjab | Rajasthan | Sikkim | Tamil Nadu | Telangana | Tripura | Uttar Pradesh | Uttarakhand | West Bengal

We Supply and Export in Listed Country.

India | Bhutan | Burma | Qatar | UAE | Israel | Italy | Japan | Kazakhstan | Kuwait | Latin America | Nepal | Nigeria | Oman | Philippines | Russia | Sri lanka | Singapore | Sudan | Uganda | US | UK | Europe | Madagascar | Venezuela | Yemen | Ghana | Angola | Malaysia | Peru | Uzbekistan | Saudi Arabia | Morocco | Poland | Canada | Ukraine | Algeria | Argentina | Spain | Colombia | Kenya | Myanmar | South Africa | Tanzania | France | Australia | Thailand | Germany | Turkey | Vietnam | Egypt | Ethiopia | Bangladesh | Brazil | Indonesia | China |